| |

|

Tour

|

The Lederer shop has all the tools needed to create a world class Deco engine. From right to left:

- Hydraulic Press

- Band Saw

- Bench Grinder

- Arbor Press

- Media Blast Cabinet

- Cylinder Hone

|

| The lathe is used to finish raw pistons and valves. |

|

|

The Bridgeport mill is used to machine blocks, finish carbs and rough cut ports. |

| A precision boring bar sizes cylinders and makes them true to the crank axis. |

|

|

Sunnen hone is used to size and finish cylinder bores. The result is perfectly round, smooth and straight. |

| Lederer motors carries a full inventory of parts to provide quick service and get you back on the track. |

|

|

It all comes together in the engine assembly room. The room is clean and well lit to facilitate holding the exacting tolerances required for a race engine. |

|

|

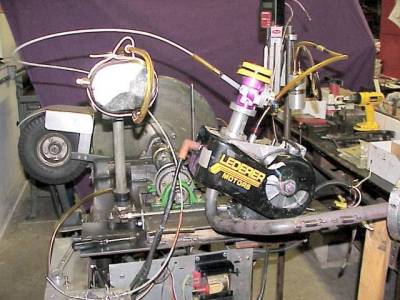

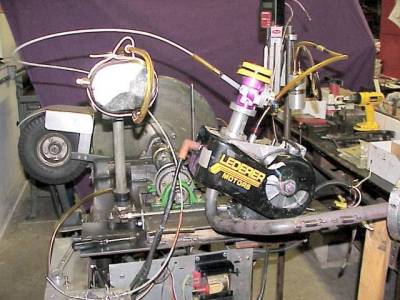

The dyno is where it is all put to the test. Lederer motors was the first to use an inertial dynomometer for quarter midget motors. An inertial dyno measures the performance of the engine the same way it is used on the track allowing exact tuning of the final product. |

Copyright © 2008, Lederer Motors, All Rights Reserved.

|

|

|